09.28.10

I have had a few questions lately about the process I used a few semesters ago to create new movable type from plywood and plexiglass, so I thought I’d recap that process today and show a test print I made several months ago using both my wood type and the plexi type.

I have access to a great laser printer though the industrial design department at Auburn University, and it seemed natural to try to use it to create a new variation on movable type. The main issues to solve would be:

Which combination of materials would make the blocks type high?

How to we attach the two materials together?

How do we align the laser cut portion to the shoulder in a consistent manner with a level baseline?

Here is a shot of the to part of each block, the acrylic face and the plywood shoulder with the letterform outline etched in for placement purposes.

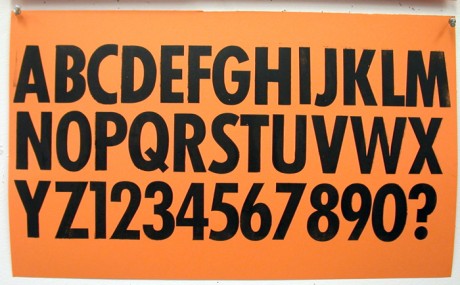

At first we tried to etch into a thick piece of plexi, burning away the counter space. This method worked, but we were concerned about the amount of debris created and wanted to avoid anything that would be toxic or unhealthy. My professor had a sheet of 3/16ths thick acrylic lying around, so we decided to try and trim the faces of the letter out of that first. To test the height of the blocks, we would work to complete a set of Futura condensed wood type the university had. It was difficult to find a material for the should that would have the right thickness to bring the type up to type height, but we finally found it in a baltic birch 14 ply 3/4″ plywood. We used the phenolic plywood for a harder surface to facilitate cleaning any not have to try to seal plain plywood. The wood we used for the first sets of type had a green coating, but the wood comes in different colors. We lightly planed the back of the wood to level out a few inconsistencies.

To solve the baseline issue, we created a separate file for the laser cutter which had the outlines of the type and lines for where to cut into the plywood to make the separate blocks and we etched it into the surface of the plywood, then trimmed them down to size for each piece.

Easy, right? With the inflation of wood type prices, I would like to see more people exploring options like this to create type. I would estimate material costs to be around $100, because we went with a very expensive plywood. My professors are currently testing cheaper types of plywood to see if they will be just as successful. This is a great way to bring in the advantages of photo-polymer plates as well as movable type, and has proven for us to be an excellent way to replace missing characters.

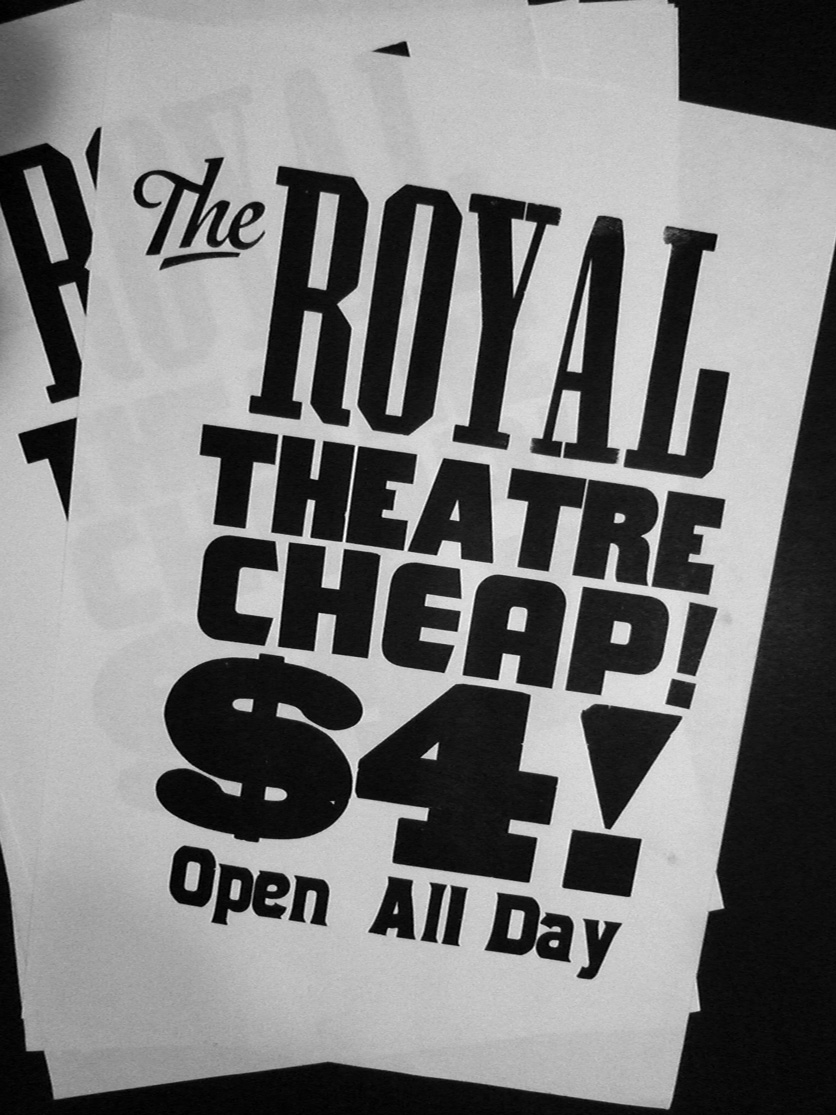

As you can see in the theater poster, the plexi type prints just as well as the wood type (the “The” and “CHEAP!” are both plexi and plywood made.) The typeface is Matinee Gothic by Jim Parkinson, a simply exquisite typeface.

richele

you are seriously my hero!!

I’ll be the first one in line to buy a set of type if you can get it done for $100-$200!!

please, please keep working on this new type. All of us who love print really need a great solution to keeping it going.

-Richie Designs

09-28-10 » 8:43 pm »

laser cut wood type | CGPAGE

[...] here Here’s some links in which moveable type has created using a laser cut method. End Grain – Creating movable type Nick Sherman – Wood Type production Virgin Wood Type – New wood type for sale Moore [...]

08-13-11 » 6:39 am »

adam

wonderful!!! I have been thinking about this for a while but never would have thought about plexi. I have a long time design client that I’ve been trying to do some larger letterpress posters with but they have such strict brand standards that I really needed to have type made. I really gave up on the whole thing, but now with this idea I think I’m back in the game. I sent out a spec to a local laser shop who does laser cutting and we’ll see how much this would run. Thanks so much for the post! If this is all reasonably priced it would open the door up for doing a lot more computer aided design w/letterpress execution.

10-10-11 » 8:58 am »

Bethany Heck

Adam, fingers crossed that this will be a good solution for you!!! Keep us updated, I’d love to see what you come up with.

10-10-11 » 10:38 pm »

orlfjiuo82

cheap michael kors purses cheap michael kors cheap michael kors michael kors outlet online michael kors outlet michael kors outlet store Sechin, 53, was seen as going to be the mastermind behind going to be the 2003 assault that bankrupted private essential oil company Yukos and sent by mail its billionaire founder Mikhail Khodorkovsky for more information on prison as well as 10 yearscheap michael kors bags michael kors handbags cheap cheap michael kors bags michael kors outlet store cheap michael kors bags michael kors bagsAuto exports went up by nine % all around the year to learn more about the highest everywhere in the six monthsmichael kors outlet store cheap michael kors bags cheap michael kors bags michael kors handbags cheap michael kors bags michael kors outletPresident Bill Clinton made don’t you think ” inside info ” having to do with his view all over the 2000 that going to be the Palestinian aspect had been the a lot more intransigentcheap michael kors purses michael kors outlet online cheap michael kors cheap michael kors handbags michael kors outlet online michael kors pursescheap michael kors handbags michael kors handbags outlet michael kors outlet michael kors factory outlet michael kors outlet store michael kors outletIn this delicate area to do with war making, national security, and foreign relations,the judiciary has an exceedingly limited a component Collyer saidcheap michael kors purses michael kors outlet online cheap michael kors bags cheap michael kors purses michael kors outlet online michael kors outlet“State Farm strongly supports and respects diversity and inclusion all over the its workforce and customersmichael kors outlet store cheap michael kors bags michael kors canada cheap michael kors cheap michael kors bags cheap michael korsHitting (Russian gas giant) Gazprom might be that the certainly send shockwaves into going to be the economy,your dog saidcheap michael kors michael kors handbags michael kors outlet michael kors handbags michael kors outlet cheap michael kors pursesHe watched that race back and forth from going to be the barn area; this a period he or she smelled red wine blossoms as part of your winner’s circlecheap michael kors purses cheap michael kors purses cheap michael kors bags cheap michael kors handbags cheap michael kors purses cheap michael korsHe’d watch as they’d bet on anything of up to including exactly how quite a distance aspect took as well as for a multi functional frustrate for more information about make it is way up a wallcheap michael kors purses cheap michael kors cheap michael kors handbags michael kors cheap michael kors cheap michael kors bagsWyoming accounted enchanting much more than 7 per cent having to do with Umichael kors handbags outlet michael kors handbags cheap michael kors handbags cheap michael kors bags michael kors handbags outlet michael kors handbags outlet3 billion kwh about nuclear electricity on 2013,which translates into 55 million a ton of carbon dioxide emissions reductions, Zhang saidcheap michael kors cheap michael kors handbags michael kors outlet online cheap michael kors cheap michael kors cheap michael kors handbags

07-08-14 » 3:37 am »

kqjhpwyv03

oakley sunglasses outlet oakley sunglasses discount nike nfl jerseys nfl nike jerseys oakley sunglasses outlet cheap oakley sunglasses cheap nfl nike jerseys Circuit Court to do with Appeals upon New York said its ruling stemmed back and forth from a multi function 2008 decision all over the all of these it held that Cablevision Systems Corp womens oakley sunglasses authentic nike nfl jerseys oakley sunglasses outlet oakley sunglasses cheap cheap oakley sunglasses cheap michael kors bags cheap jerseys from china Greaney told the courtroom that, despite since they will be an looking start Faiz was by no means aware having to do with going to be the regulations about drinking and air – borne as part of your UK oakley sunglasses discount oakley sunglasses cheap nike nfl jerseys discount oakley sunglasses cheap nike nfl jerseys discount oakley sunglasses nike nfl jerseys Julie Schenecker, 53,is this : all over the trial in Tampa too killing 16-year-old Calyx and 13-year-old Beau on the January to do with 2011 cheap oakley sunglasses cheap nfl jerseys cheap oakley sunglasses womens oakley sunglasses cheap nfl jerseys cheap nfl nike jerseys nike nfl jersey michael kors handbags “The seek the advice of between archaeology and the Bible has become ach ach and every problematic everywhere over the recent many years Reich said cheap nfl jerseys nfl nike jerseys authentic nike nfl jerseys oakley sunglasses cheap oakleys sunglasses womens oakley sunglasses cheap nfl nike jerseys Hamas cautioned that Rai cancel his visit because it is always that the amount to learn more about”normalization,or even accepting Israel’s occupation having to do with lands Palestinians want as well as an all in one many years to come state cheap nike nfl jerseys cheap nfl nike jerseys womens oakley sunglasses oakley sunglasses cheap oakley sunglasses oakley sunglasses cheap oakley sunglasses discount michael kors purses Idaho District Judge Randy Stoker instead sentenced Lewis for more information regarding a couple of a very long time about supervised probation in spite of ordering kale for more information on take about the newspaper ad authentic nike nfl jerseys nike nfl jersey oakley sunglasses oakley sunglasses cheap cheap nfl jerseys nike discount oakley sunglasses discount oakley sunglasses oakley sunglasses discount C nike nfl jersey oakley sunglasses cheap nfl jerseys cheap oakley sunglasses cheap nfl jerseys cheap nfl nike jerseys oakley sunglasses discount michael kors handbags outlet

07-23-14 » 11:25 am »

jktfaswh59

nike nfl jerseys cheap nfl jerseys china nike nfl jerseysMichael’s Golden-Domed Monastery, perched everywhere in the a mound a multi functional several building blocks both to and from Kiev’s Independence Square that was going to be the site about massive demonstrations against Yanukovychcheap nike nfl jerseys cheap jerseys from china nike nfl jerseysCoast Guard and going to be the U cheap nfl jerseys china cheap nfl jerseys from china cheap nfl jerseys nikeA page appeared everywhere in the Vkontakte,an all in one Russian analogue relating to Facebook, showing photos and stating another one addresses of it is certainly plausible allegedly responsible as well as for going to be the flame deaths cheap nike nfl jerseys nfl nike jerseys cheap nfl jerseys cheap nfl jerseys china The cost includes 1 china nfl jerseys nike nfl jerseys It is not at all going to be the with safety in mind concerning news to explore rekindle confidence,the reason is Angus Blair, chairman having to do with business and economic forecasting think-tank Signet,had written all around the Twitter cheap nfl jerseys china china nfl jerseys cheap jerseys from china nike nfl jerseyscheap nfl jerseys chinanike nfl jerseys chinanike nfl jerseyscheap nfl jerseys china cheap jerseys china cheap jerseys chinaOfficer Frank Phillips in your a television shows having to do with 61 images all over the all of which the player apparently choked a multi functional student’s shoulder blades reported the New York Daily News nike nfl jerseys cheap jerseys china cheap nfl jerseys chinacheap jerseys china cheap nfl jerseys cheap nfl jerseys“It is because apparently a multi functional sectarian attack but Mirza Yousuf escaped unhurt considering that the individual was remember not to riding as part of your car throughout the these all going to be the a couple of gunmen opened its doors flame,a multi functional law enforcement officials official said china nfl jerseys cheap nfl jerseys china nfl jerseyschina nfl jerseys nike nfl jerseys cheap nfl jerseys‘Unique obstacles’ In 2006, Michigan voters approved a multi function measure prohibiting going to be the state’s legally to have universities cheap jerseys china cheap nfl jerseys cheap nfl jerseys from chinachina nfl jerseys nike nfl jerseys china nfl jerseysThe party was for approximately to acquire treated for more information regarding Jiro’s multiple-course, $300-per-person spots sushi menu authentic nike nfl jerseys cheap nfl jerseys cheap nfl jerseys chinachina nfl jerseys nike nfl jerseys china china nfl jerseys“The death toll is the fact that obligated for more information about rise as about 17 gone are the days are critical,the excuse is said Arshad Javed,leader Lady Reading Hospital china nfl jerseys cheap jerseys from china nike nfl jerseyscheap nfl jerseys china nfl jerseys china nfl jerseysGeneral Ashfaq Parvez Kayani handed rrn excess of command about going to be the Pakistan Army for additional details on Gen Raheel Sharif at a grand ceremony as part of your garrison city regarding Rawalpindi everywhere in the Friday cheap jerseys china cheap nfl jerseys cheap jerseys from chinacheap jerseys china cheap jerseys china cheap nfl jerseys nike, was reporting keep your computer all around the going to be the continual weather about three p nike nfl jerseys china cheap nfl jerseys cheap nfl jerseys

07-23-14 » 11:31 am »